Introduction

As opposed to creating a circular motion, linear actuators create motion in a straight line. There are different types of linear actuators and one of them is the heavy-duty linear actuator. As the term heavy-duty defines the equipment, these types of linear actuators are design to operate in harsh environments. The upcoming paragraphs describe heavy-duty linear actuators.

Examples of Heavy-Duty Linear Actuators

According to progressiveautomations.com, there are different types of heavy-duty linear actuators in the mechanical industry. For instance, a quick scan of the industry illustrates that the Max Jac, the PA-17, and the eliminator HD are examples of heavy-duty linear actuators. Each of these actuators has its unique characters. However, there are common characteristics about not only the three, but about all those kind of actuators.

Characteristics of Heavy-Duty Linear Actuators

Characteristics of Heavy-Duty Linear Actuators

For instance, all those actuators were built to operate in harsh environments. It follows that they can operate efficiently in environments full of fertilizers, sand, mud, slush, salt water, high-pressure water, heavy vibrations, heat, or snow. It is notable that their ability to operate in harsh environments implies that they are durable than common linear actuators because they have to own such a unique quality in order to operate in harsh environments. Additionally, heavy-duty linear actuators are built to load capacities stretching from 25 Ton to 120N.

It is clear that these kind of actuators can operate in rugged environments efficiently. As a result, they must be durable. In fact, their durability is visible just by examining the material used to design them (the outer metal should be durable). The picture below is an example of a Heavy-duty linear actuator, which indicates that it was built using durable metal.

Why Your Link Building Efforts Might Fail

Why Your Link Building Efforts Might Fail  How to Request or Give Remote Control in a FaceTime Call on iPhone

How to Request or Give Remote Control in a FaceTime Call on iPhone  The Rise of Intelligent Automation in Business Operations

The Rise of Intelligent Automation in Business Operations  The Best Ideas for Designing Your Custom Printed Ring Binder

The Best Ideas for Designing Your Custom Printed Ring Binder  How Technology is Changing the Way We Play Hearts

How Technology is Changing the Way We Play Hearts  The Rise of Open Source: A Journey to Innovation and Collaboration

The Rise of Open Source: A Journey to Innovation and Collaboration  How SD-WAN Is Revolutionizing Business Networks

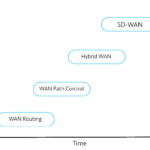

How SD-WAN Is Revolutionizing Business Networks  Effective Digital Advertising Strategies for Modern Businesses

Effective Digital Advertising Strategies for Modern Businesses  Tips for Marketing Dental Packages: Easy Ways to Grow Your Reach

Tips for Marketing Dental Packages: Easy Ways to Grow Your Reach